Description

Custom-made insoles can provide personalized comfort and support for individuals with specific foot conditions or preferences. 3D printing technology has made it possible to create custom insoles that are precisely tailored to an individual’s foot shape and requirements. Here’s how the process typically works:

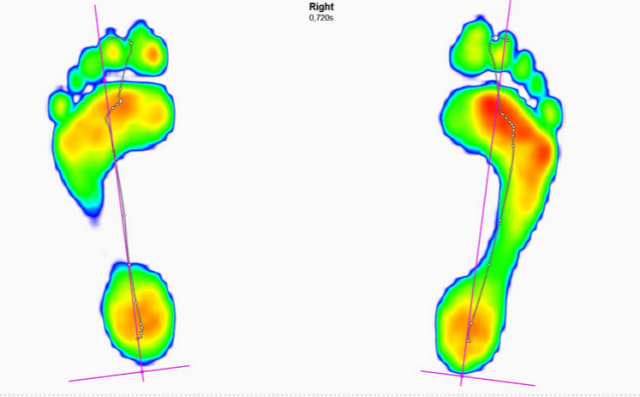

Foot scanning: The first step is to create a digital model of the foot. This can be done using a 3D scanner or by taking a series of measurements manually. The scanner captures the shape and contours of the foot, including arch height, pressure points, and any specific problem areas.

Design and customization: Once the digital foot model is obtained, it is used to design the custom insole. This involves determining the optimal support structures, cushioning areas, and other features based on the individual’s needs. The design can be adjusted to accommodate specific foot conditions like flat feet, high arches, or pronation issues.

3D printing: The designed insole is sent to a 3D printer that uses a suitable material, such as thermoplastic polyurethane (TPU) or a similar flexible material. The printer follows the digital design and deposits layer by layer of the material to build the insole. The printing process can take several hours, depending on the complexity and size of the insole.

Finishing touches: After the 3D printing is complete, the insole may require some additional post-processing. This can involve removing any support structures used during printing, smoothing the surface, or adding specific features like additional cushioning or orthotic inserts.

Fitting and testing: Once the insole is ready, it can be placed inside the shoe for fitting. The individual can wear the shoes and test the insoles for comfort, support, and any necessary adjustments. If needed, minor modifications can be made to optimize the fit and performance of the insole.

It’s important to note that the process and materials used may vary depending on the specific 3D printing technology and equipment available. It’s advisable to consult with a professional, such as a orthopedic specialist, who can guide you through the process and ensure that the custom-made insoles meet your specific needs